The Ultimate Guide to UV Printer Ink: Revolutionizing the Printing Industry

In today’s fast-paced digital world, the demand for high-quality and efficient printing solutions has skyrocketed. Among the numerous advancements in printing technology, UV printer ink stands out as a groundbreaking innovation that is transforming various industries. This comprehensive guide will delve deep into the world of UV printer ink, exploring its characteristics, benefits, applications, and much more.

Understanding UV Printer Ink

UV printer ink is a specialized type of ink that utilizes ultraviolet light to cure or dry the ink as it is printed. Unlike traditional inks that evaporate or dry through oxidation, UV inks harden instantly when exposed to UV light, making them remarkably versatile and efficient.

What Makes UV Printer Ink Unique?

The unique curing process of UV printer ink is what sets it apart from conventional inks. Here are key features that define this ink:

- Fast Drying: The ink cures immediately upon exposure to UV light, facilitating quick production times.

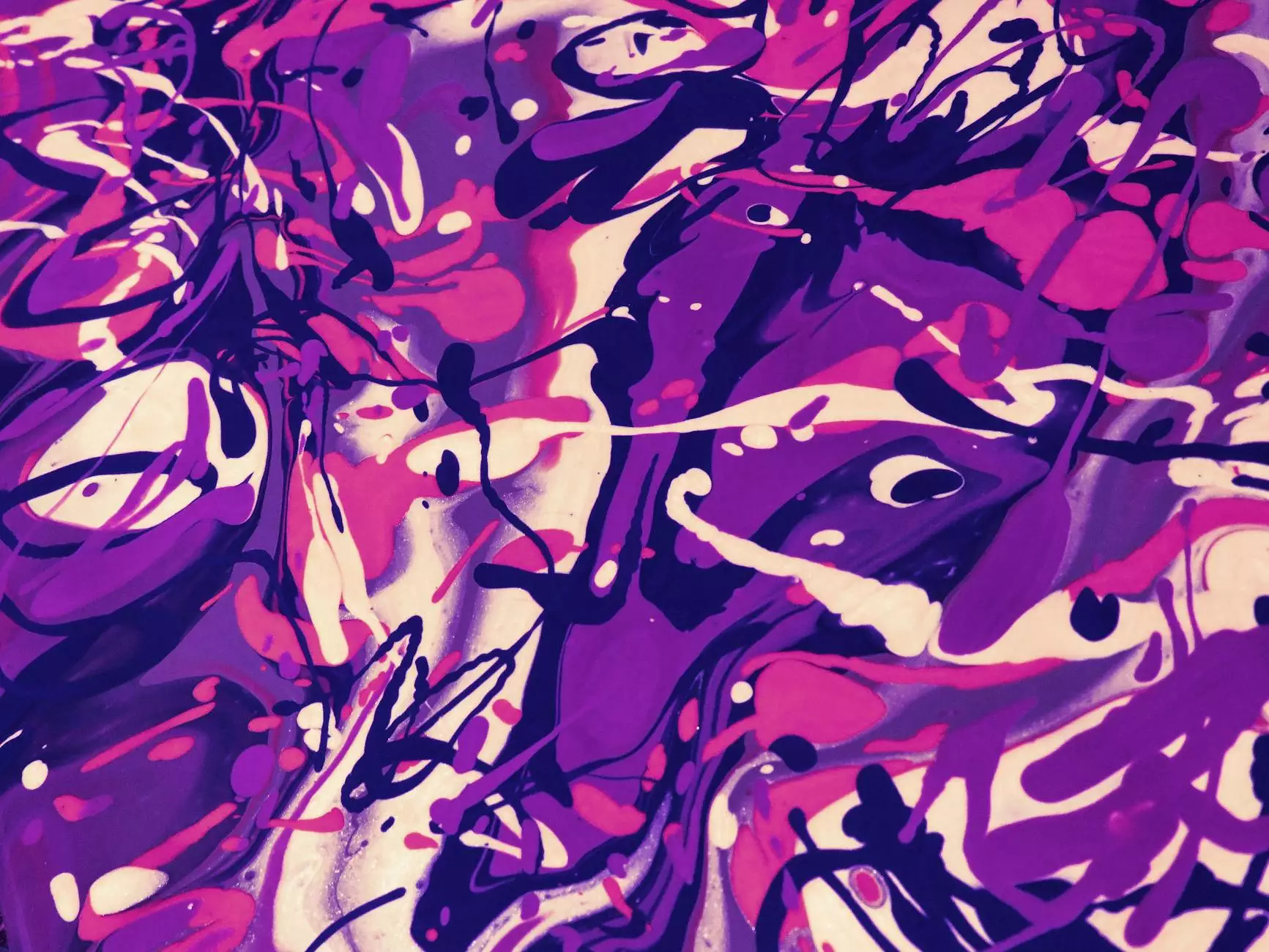

- Vibrant Colors: UV inks often boast brighter and more vivid colors than their solvent or water-based counterparts.

- Durability: The cured ink is resistant to scratches, smudges, and fading, making it suitable for both indoor and outdoor applications.

- Eco-friendly: UV inks contain fewer volatile organic compounds (VOCs), contributing to a more eco-friendly printing process.

- Flexibility: These inks can adhere to a variety of substrates, including different types of plastics, metals, glass, wood, and more.

Advantages of Using UV Printer Ink

Adopting UV printer ink can provide a myriad of advantages, enhancing the overall printing process and final output. Here’s a detailed look at the benefits:

1. Increased Productivity

Since UV inks dry instantly, they streamline the printing process. This rapid curing allows businesses to produce more prints in a shorter time frame, improving overall efficiency and productivity.

2. High-Quality Prints

The vibrant colors and sharp details achievable with UV printer ink ensure that the prints stand out. The superior quality makes it ideal for high-end applications, such as marketing materials and product packaging.

3. Versatile Applications

UV inks can be used on a wide variety of surfaces. From paper and cardstock to rigid materials such as wood and metal, the versatility of UV printer ink allows businesses to expand their service offerings and meet customer demands more effectively.

4. Cost-Effective Solutions

While the initial investment in UV printers may be higher, the long-term benefits such as reduced ink usage, faster production times, and the elimination of additional coating applications make it a cost-effective choice for many printing businesses.

5. Environmentally Friendly Options

As consumers become more environmentally conscious, businesses that prioritize eco-friendly practices can benefit from utilizing UV printer ink. With lower VOC emissions and recyclable materials, UV printing aligns with sustainable practices.

Applications of UV Printer Ink

The versatility of UV printer ink opens up numerous possibilities across various industries. Here are some significant applications:

1. Signage and Displays

From vibrant banners to outdoor signage, UV inks are perfect for creating eye-catching displays that withstand harsh weather conditions. The durability and color retention of UV prints make them a preferred choice for many businesses.

2. Packaging

UV printing is widely used in the packaging industry, allowing brands to create stunning product packaging that catches the consumer's eye. The ability to print directly onto substrate eliminates the need for labels, offering a cleaner appearance and reducing waste.

3. Decor and Interior Design

Custom wall art, printed furniture, and decorative pieces can be made with UV printer ink, providing unlimited design possibilities. The durability of UV prints means that they retain their vibrant colors over time, making them ideal for interior applications.

4. Industrial Applications

UV inks are used in various industrial applications, including printing on parts and components that require high performance and longevity. This includes electronics, automotive parts, and more.

5. Promotional Products

Businesses often use UV prints on promotional items such as corporate gifts, apparel, and accessories. The high-quality prints enhance brand visibility and make lasting impressions on customers.

Comparing UV Inks with Other Printing Inks

It is essential to understand how UV printer ink compares to other types of inks to choose the best option for your needs. Here’s a comparison:

1. UV Inks vs. Solvent Inks

Solvent inks contain volatile organic compounds that can emit strong odors and harmful emissions. In contrast, UV printer ink is much more environmentally friendly, producing fewer emissions while providing faster drying times and superior durability.

2. UV Inks vs. Water-Based Inks

Water-based inks tend to absorb into porous materials, whereas UV inks sit on the surface, creating vivid images. While water-based inks may be more eco-friendly, UV inks offer better adhesion to a wider range of substrates.

3. UV Inks vs. Latex Inks

Latex inks offer flexible applications but may take longer to dry and harden compared to UV printer ink. UV inks provide immediate curing and can create a thicker layer of ink on the surface, enhancing the texture of the final product.

Choosing the Right UV Printer Ink

Selecting the perfect UV printer ink for your printing business involves several considerations. Here are some tips to help you make the right choice:

- Substrate Compatibility: Ensure the ink is compatible with the materials you plan to print on for the best adhesion and quality.

- Color Range: Look for inks that offer a wide color gamut to enhance your design possibilities.

- Drying Speed: Depending on your production speed needs, select an ink that cures quickly to match your workflow.

- Durability: Choose inks known for their resistance to fading and scratching for long-lasting prints.

- Cost Efficiency: Assess the cost per print compared to other inks and consider the total expenditure on maintenance and cleaning.

Future Trends in UV Printing

As technology continues to advance, the future of UV printer ink looks promising. Here are some trends to watch:

1. Increased Customization

Demand for personalized products continues to rise, pushing the envelope for customization in printing. Advancements in UV printing technology will support more intricate designs and enhanced capabilities for tailored services.

2. Sustainability Focus

The push towards sustainability will lead to more eco-friendly UV inks. Manufacturers are likely to research bio-based options that provide the same benefits while being kinder to the environment.

3. Expanded Substrate Options

Continued development in UV ink formulations will result in greater adhesion properties on innovative materials, expanding the range of substrates that can be printed on.

Conclusion

In summary, UV printer ink is a game-changer in the printing industry, offering unique benefits that enhance productivity, quality, and environmental friendliness. As businesses like Boston Industrial Solutions continue to embrace advancements in printing technology, the adoption of UV inks is likely to rise, paving the way for innovative applications and solutions in the future. By understanding the ins and outs of UV printer ink, businesses can make informed decisions that enable them to stand out in a competitive landscape. Whether you’re in signage, packaging, or any other industry, integrating UV printer ink into your offerings could be your ticket to success.